Switch gears are generally used in an electrical set up in order to facilitate a disconnection of an electrical equipment from the main supply line. It is quite obvious that an electrical setup is susceptible to harms in case of frequent fluctuations, unsteady power supply and lack of maintenance. Switchgear are extremely useful to protect electrical equipments from all these problems.

They disconnect the equipments from the main supply line and make room for professionals to make necessary adjustments in the equipments. Electrical Switch gears are used both in domestic as well as industrial sectors in order to make electrical equipments more efficient and effective.

Types of Electrical Switchgears

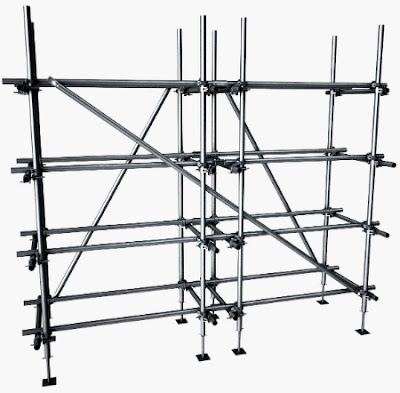

Electrical switchgear manufacturers produce and market different types of switchgear all over the world and so it is important for clients to choose the right type of switchgear in order to have the desired result. Some switch gears are base on air while some depend on oil to deliver the desired performance.

Certain circuit breakers depend on gases like sulphur hexafluoride in order to disconnect the electrical equipments. Hybrid switchgear are also available where a combined function of the air and the gas is necessary to make the disconnection happen. It is to be kept in mind that these switch-gears have to be maintained properly in order to have the best possible performance for a long time.

Safety Issues and Concern

As these switch gears are regarded as important industrial equipments it is to be kept in mind that there are several safety issues that users need to consider while using these equipments. Many Electrical Switchgear Suppliers equip their products with trapped key interlocking system that ensures a safe operation of the gear.

Apart from this, switchgear are also taken through strict quality control measures as well as trials and testing in order to ensure safety. It is important for users to be able to use these switch-gears safely and in a proper fashion in order to have the best possible results

|

| Electrical Switch-Gears |

Types of Electrical Switchgears

Electrical switchgear manufacturers produce and market different types of switchgear all over the world and so it is important for clients to choose the right type of switchgear in order to have the desired result. Some switch gears are base on air while some depend on oil to deliver the desired performance.

|

| Types of Switchgears |

Safety Issues and Concern

As these switch gears are regarded as important industrial equipments it is to be kept in mind that there are several safety issues that users need to consider while using these equipments. Many Electrical Switchgear Suppliers equip their products with trapped key interlocking system that ensures a safe operation of the gear.

Apart from this, switchgear are also taken through strict quality control measures as well as trials and testing in order to ensure safety. It is important for users to be able to use these switch-gears safely and in a proper fashion in order to have the best possible results